So I've kind of become obsessed with mastering the techniques of sewing a button-up collared shirt (or shirt dress!) lately. I've made several of them in the past but it's never a perfectly smooth ride. The hardest part of making a shirt, for me anyway, is sewing the stupid collar stand. Everything about it -- attaching it to the shirt, attaching it to the collar, edge-stitching around the curves, and sewing a buttonhole on it. I dread it all every time, but I'm determined to keep practicing and trying to find ways to make it go more smoothly.

I've discovered a technique in attaching the collar/stand that works considerably better for me than the other methods I've tried. It's not necessarily a technique -- it's more just a change in the order of construction. I don't think this is new or revolutionary -- in fact, Peter of Male Pattern Boldness used a similar method in his Colette Negroni sew-along when he was making the version of the shirt with the traditional collar stand (see here). But, his is the only tutorial I've seen so far that demonstrates this order of construction, and he does a mirror image construction to what I prefer. It's a hard method to search online because there's no name or distinguishing feature for it. So, I'm just going to throw it out to the Internet again and see if anyone catches.

Most patterns have you construct the collar then sandwich it between the collar stand pieces and stitch everything together. Then you have to attach this whole already-sewn thing to the shirt neckline. This is what I've always seen in commercial patterns and other tutorials:

This has always resulted in a fiddly mess for me because it's harder to get the collar stand edge to perfectly align with the front plackets. The method I prefer is to attach the outer collar stand to the shirt by itself, then attach the collar to that, and then sew on the inner collar stand. Here's how to do all that:

1. Sew the body of your shirt as usual or as instructed in the particular pattern you're using. Make sure you've turned/attached your front plackets and done any shoulder-seam topstitching before attaching the collar. Stay-stitch the neckline of your shirt so it doesn't stretch out beforehand.

2. Fuse (or sew) interfacing to the upper collar and the outer collar stand piece. To reduce bulk in the finished garment, cut away the seam allowance in the interfacing before fusing it. I didn't reduce mine all the way around, though you definitely could (should?).

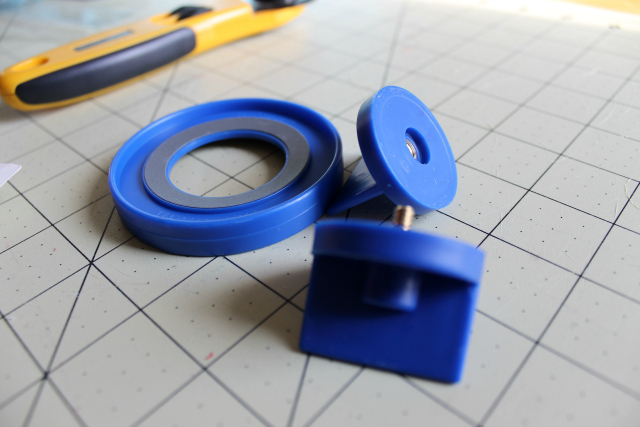

3. To make a neat collar, it helps to start with properly sized collar and collar stand pieces. If you're using a pattern that has the same pattern piece for both the upper collar and the under collar, you're going to want to trim down the edges of your undercollar by 1/8" all the way around. I also do this on the inner collar stand. When pinning and sewing later, you will align the raw edges up as usual, and the smaller piece will stretch a bit to fit. Why do this? By reducing the size of the inner & under pieces, the seams will roll more naturally to the underside, and you won't get puckers when sewing the inner collar stand.

(Please don't use a rotary cutter directly on your table. I removed my cutting mat for the photo so you could see the cut edges more clearly).

4. With right sides together, pin the bottom edge of the interfaced collar stand piece to the shirt neckline, matching centers and any notches. It helps to clip some parts of the shirt neckline so it conforms to the curve of the stand.

The ends of the collar stand will protrude from the front edges of the shirt by the given seam allowance.

Stitch this seam. Trim the seam allowance and press up. I always leave a more considerable seam allowance at the ends. It may be bulkier but it's easier to handle in subsequent steps.

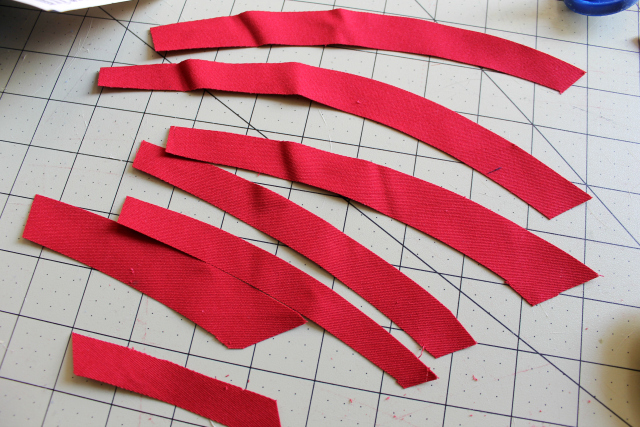

5. Sew the sides and bottom edges of the upper collar piece to the under collar piece, right sides together. Leave the top edge unstitched.

Trim the seam allowances if necessary, turn right side out, and work your magic to get sharp collar points. (I always try using this tip from this tutorial, though it's not always 100% successful.) Press the collar, rolling the seam slightly under so it's not visible. Top-stitch 1/4" from the edge if desired. You can baste the top collar edge now, though I typically don't.

6. Pin and baste, or just pin, the whole collar piece to the interfaced collar stand, which has already been attached to the shirt. Make sure that the interfaced side of the collar (upper collar) is facing up. The uninterfaced side of the collar (under collar) will be facing the interfaced (outer) collar stand. Got it?

7. NOW is when you attach the uninterfaced collar stand piece (inner collar stand) to the whole shebang, right sides together, matching centers and edges. The collar will be sandwiched in between the two pieces. Before pinning, fold up the seam allowance of the uninterfaced collar stand on the bottom edge so that it mirrors its interfaced counterpart. You can press up that whole edge at this point, too, but I prefer to do it later.

8. Stitch this seam, making sure the stitches butt up (hehe) directly in line with the front placket edge. Backstitch securely.

Trim this seam allowance and clip the curve, but make sure to leave yourself some wiggle room with the S.A. at the edge. Turn right side out and press. See how well the edges line up? This is where it helps to have more of a seam allowance inside because it's easier to push it in and out of the way from the bottom edge. I've found that a tiny, fraying S.A. is more stubborn.

9. Press under the lower seam allowance on the inner collar stand so the edge just covers the seam line.

10. You can slip-stitch this in place (more common in women's wear), or pin from the right side and edgestitch all the way around. For the record, edgestitching is just topstitching at 1/8" or 1/16" from the edge.

I've still never achieved perfect edgestitching, but it does help to use my blind hem foot for this process. It has a sliding guide that I can line up with the edge of the seam. I've ordered a stitch-in-the-ditch foot that has a shorter, metal guide that I hope will offer more stability than this lopsided plastic thing. It hasn't arrived in the mail yet but I'll keep you posted on how well it works!

11. The collar's done! Now finish the rest of your shirt/dress and post that beauty on your blog or whatever.

[ Shirtdress pattern is McCalls' 6696 from spring 2013. Fabric is vintage cotton from Etsy. The sleeves are just rolled up here because they're not hemmed yet. ]

As you may have determined, this collar-sewing method is not drastically different from what you've probably seen before. HOWEVER, doing it in this order gives you more control of where the collar stand lines up with the front plackets, and lowers the risk of getting wonky edges and seam allowances that refuse to stay tucked in place under the inner collar stand.

I hope this makes sense. How do you sew perfect collars? Let me know if you've tried this method, tried something better, or have any questions!